Naše nabídka služeb

Kyslíko-palivové

hořáky s povrchovým směšování

Leštění plamenem

Ruční výroba

Příslušenství

O společnosti

Již přes 10 let poskytujeme našim klientům výrobky a služby v oblasti sklářského průmyslu.

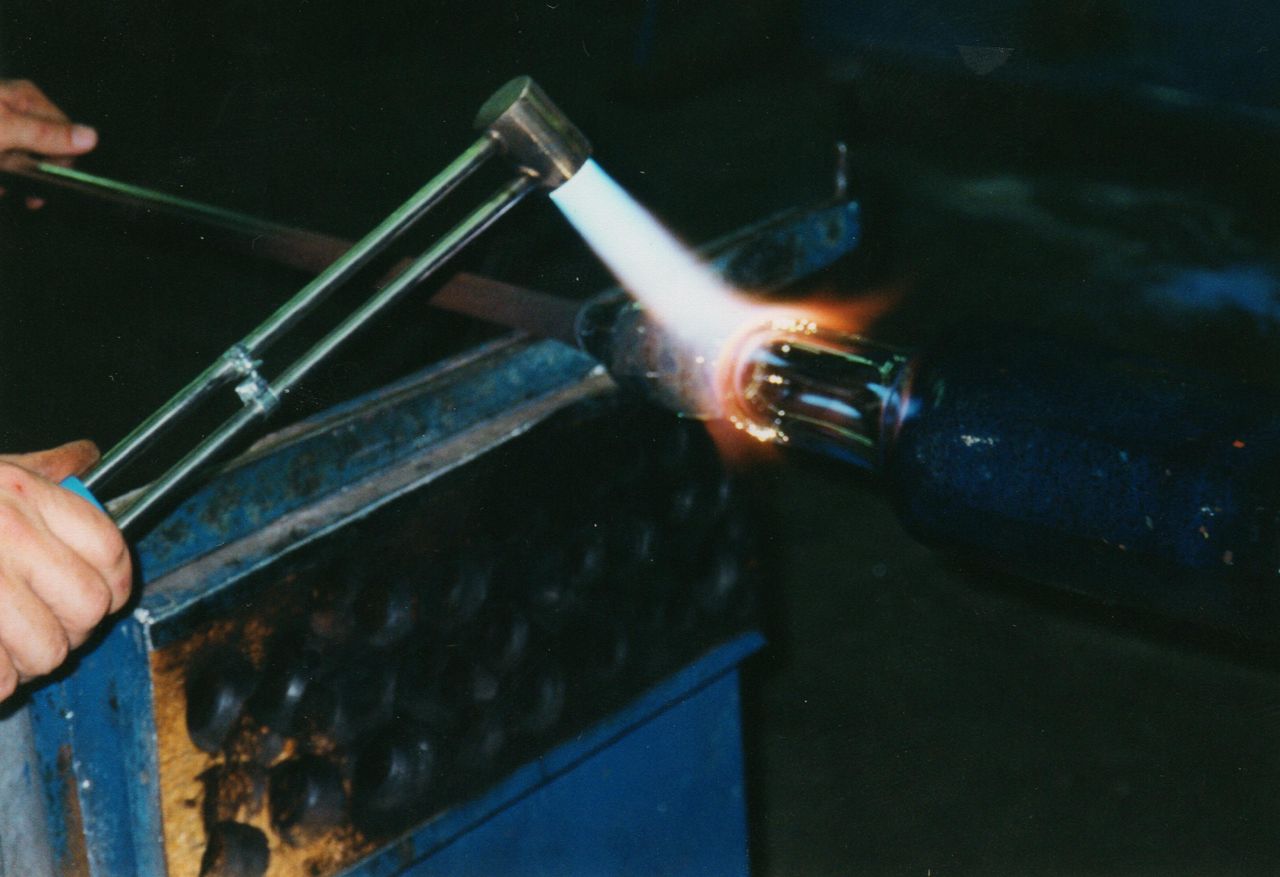

Nabízíme kyslíko-palivové hořáky nejvyšší kvality pro leštění plamenem a ohřívání ručně vyráběného skla, včetně kompletního příslušenství. Tyto hořáky rovněž sami využíváme k vlastní ruční výrobě skleněných výrobků.

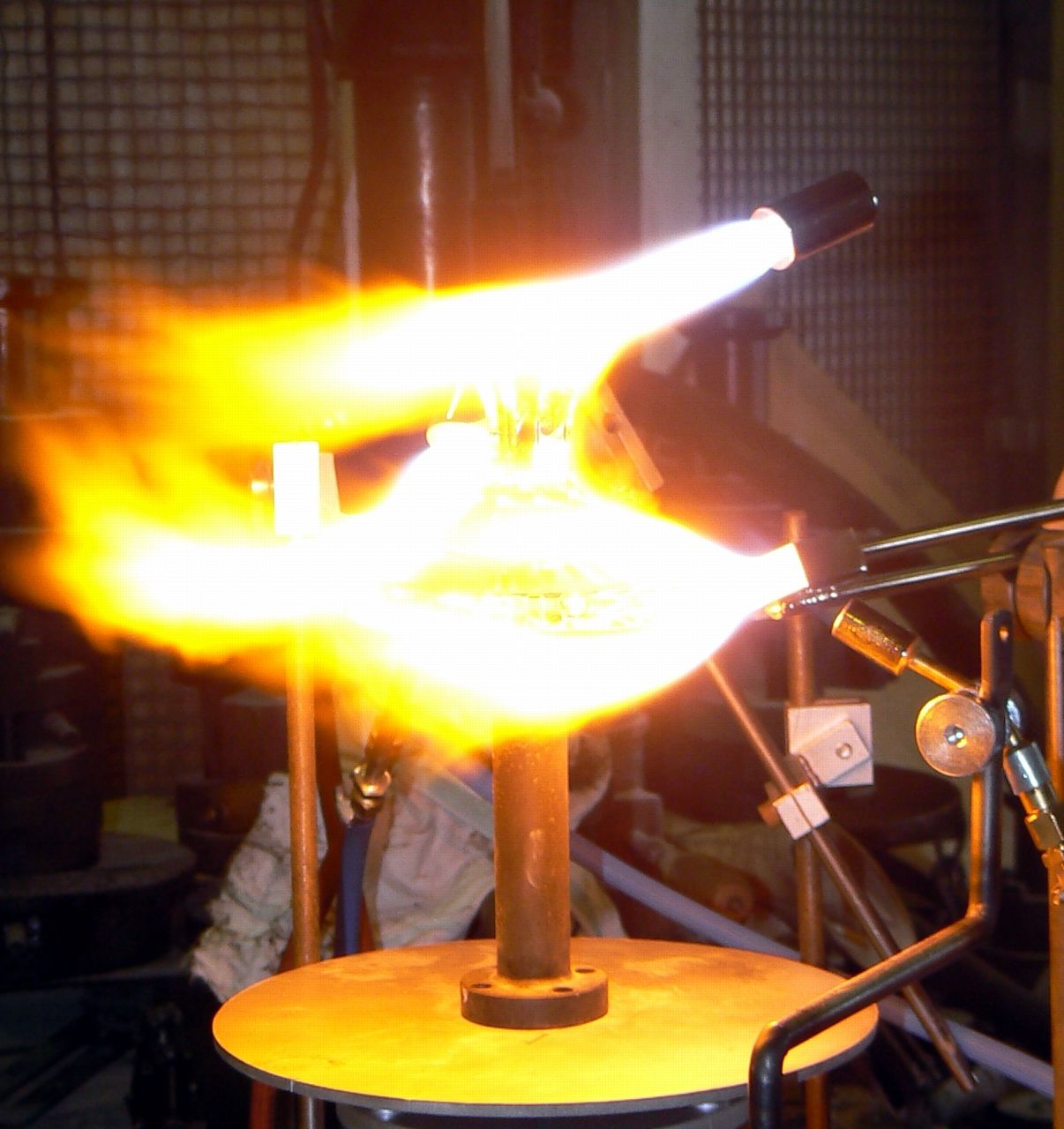

Firmám i soukromníkům jsme dále schopni zajistit leštění plamenem používané u kvalitních lisovaných výrobků z kategorie užitkového skla. Díky leštění plamenem jsou výrobky zbavovány výčnělků způsobených formou a dalších nerovností. Výsledkem je dokonale hladký a lesklý povrch, který je navíc odolnější vůči mechanickému poškození.

Každému z našich klientů poskytujeme vždy prvotřídní služby. Firmy s námi navazují spolupráci opakovaně, což nás utvrzuje v tom, že děláme svou práci dobře a děláme ji s radostí i nadále.

Fotogalerie

Napište nám

BELUS s.r.o.

Suchý Vršek 2131/15

158 00 Praha 5IČO: 24189987

DIČ: CZ24189987Kontaktní osoba: Ing. Jan Hladovec

Komunikace: Česky, Anglicky (Polsky, Rusky, Ukrajinsky je možná domluva)